Automotive Applications

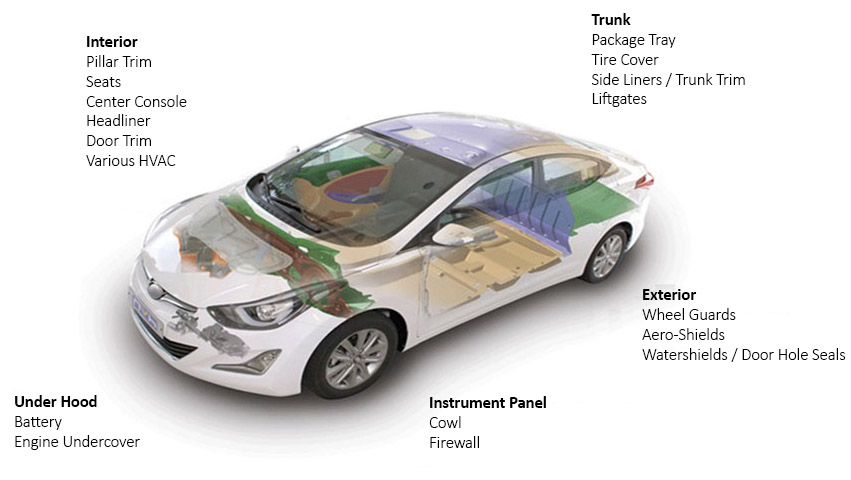

Noiselite™ products are ideal for various interior applications from sound absorption to filling voids. Our product supports superior sound absorption due to the fiber design and configuration. In addition, it is light weight to lower vehicle operational costs. We offer a white and black scrim for identification and performance reasons and offer customization. Noiselite™ can be die cut, sealed, and applied to the specific interior application with various adhesives.

Insulator & Acoustic Pad Applications

Uses & Conversion

Sound Absorption

Using engineered Hexaflower™ fibers to absorb more sound energy than traditional fiber structures, Noiselite™ delivers high sound absorption at a low weight. From roof liners to door trim to trunk floor systems, the exceptional sound absorption helps produce a quieter ride.

Vibration, Squeak & Rattle Control

A patented construction using a hybrid horizontal/vertical structure provides Noiselite™ with excellent compression and recovery that makes it a perfect solution to eliminate noises caused by annoying vibrations, squeaks and rattles.

Fill Voids

Noiselite™ is manufactured using a unique PP microfiber and Hexaflower™ staple fiber combination that results in a microfiber material that retains its shape and thickness over time. That, combined with the variety of thicknesses and weights available, makes it the ideal solution to filling spaces and voids while providing excellent sound absorption.

Conversion Edge Seal

Noiselite™ can be converted using multiple edge seal finishes to meet your aesthetic needs – die cut for a simple “pinched” edge, heat seal for a sealed flat edge, or stitch seal for an improved decorate edge.

Attachment Applications

PSA, lamination, hot melt, heat stake and ultrasonic welds are among the various adhesion methods that can be used to attach Noiselite™ to a variety of surfaces for added sound absorption qualities on parts such as cargo/trunk trims, door hole seals, package trays and more.

Other Applications

Automotive

Aerospace

Rail

Off Road Vehicles

Commercial Vehicles

Marine