Noiselite™: Technical Performance

Noiselite™ is an engineered, technical non-woven product, designed specifically with acoustic absorption in mind. With low surface density, high compression recovery, and excellent low-frequency sound absorption, Noiselite™ offers the best value to the growing NVH market providing a variety of features and benefits.

- Provides high sound absorption at a lower weight for better fuel efficiency.

- Exceptional low frequency sound absorption provides for a quiet ride.

- High loft with excellent compression and recovery supports longer lasting sound absorption.

- Innovative design utilizes a unique microfiber blend to maximize acoustic absorption.

- Limitless applications range from sound absorption, to squeak & rattle control, to filling voids.

- Unique construction allows for a variety of processing options including multiple edge seal and adhesion methods.

Innovative Design

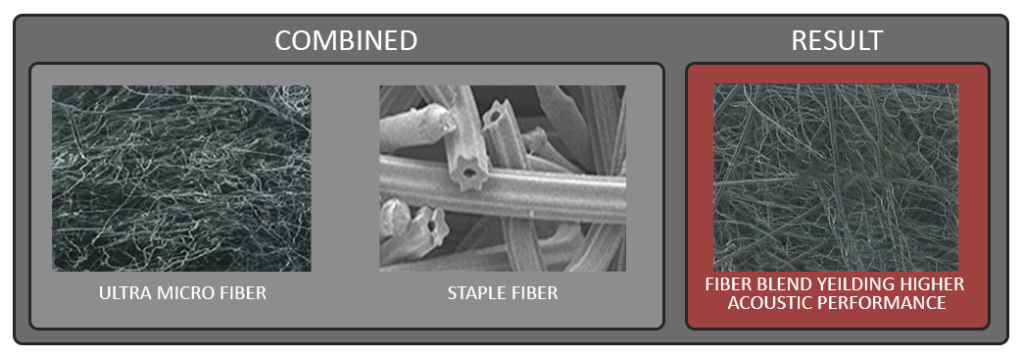

Our VM series product utilizes a blend of both PP microfibers and engineered PET fibers, a combination utilized to maximize acoustic absorption. The small diameter of our PP fibers allow for an increase in the number of total fibers, thus maximizing fiber-to-fiber contact and overall fiber surface area.

Our engineered Hexaflower™ PET fibers are shaped to further increase surface area. The goal is to create as many surfaces in which incident sound energy can vibrate against, which in turns converts acoustic energy into thermal energy, reducing overall sound levels.

Noiselite™ Technology

Noiselite™ is an NVH material developed for use in the application of sound absorption. It is classified as a nonwoven, microfiber material meaning it is constructed of small thin strands of fiber. The primary construction consists of three main layers bonded together.

- Top layer – non-woven polypropylene scrim

- Middle layer – Fiber “web” of polypropylene and polyester blend

- Bottom layer – non-woven polypropylene scrim

Sound Absorption

Noiselite™ utilizes a blend of PP microfibers with engineered PET staple fibers to produce a new, high performance sound absorption material. The size and structure of the fibers allow for a greater quantity of fibers in the material. Our goal was to create as many surfaces in which incident sound energy can vibrate against in order to convert acoustic energy into thermal energy to reduce overall sound levels. The fibers combined with the overall construction create a product with greater sound absorption at lower weights.

- The top and bottom scrim is designed to provide structure to the material while allowing air to easily pass through to the web and assist in sound absorption.

- The web absorbs energy from sound waves and dissipate them into the fibers.

- Is constructed of 55% PP microfiber and 45% engineered PET staple fiber called Hexaflower™.

- The small diameter of our microfibers allow for an increase in the number of total fibers , maximizing fiber-to-fiber contact and overall fiber surface area.

- The unique Hexaflower™ PET fibers are shaped to further increases the overall surface area (inside and out).

Random Incidence Sound Absorption

Random Incidence Sound Absorption Coefficients

in a Small Reverberation Room (SAE J2883)

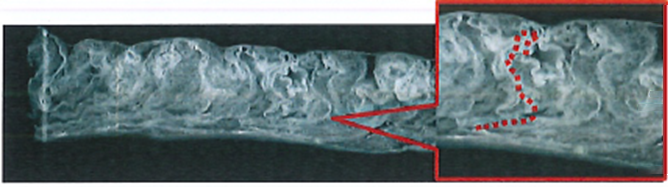

Compression Resiliency

The unique construction of Noiselite™ results in a material that retains its shape and thickness over time, sustaining its sound absorption abilities, and providing an ideal solution for filling voids.

- The PET fibers used to produce Noiselite™ are short and “springy”, providing excellent loft, compressibility, and recovery.

- A patented method for forming a vertical structure further helps with compression resiliency and loft, whereas most competitive products utilize a completely horizontal structure which is prone to losing its resiliency over time

Product thickness plays an important role in acoustic absorption, and Noiselite™ is able to maintain its thickness over time to maintain sound absorption.

NOISELITE™